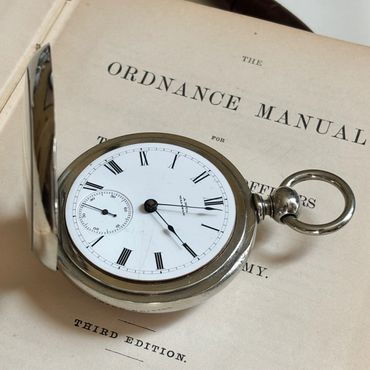

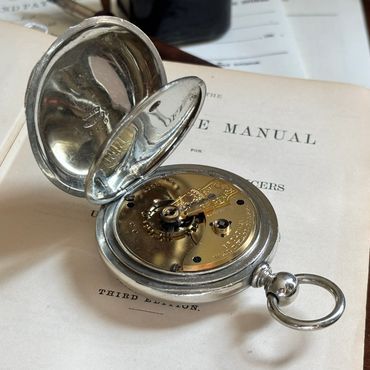

Waltham "Broadway" 18-size 7-jewel Model 1877

(scroll down for more pictures!)

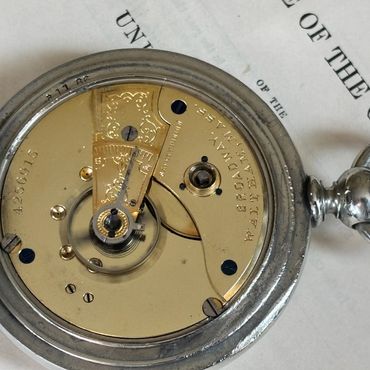

An unpretentious workhorse for the common man; this is a very late production Model 1877 in key-wind and key-set configuration, and the serial number 4256915 dates it to 1890. By that time, key-wind watches were old-fashioned but they were cheaper than stem-wind models due to simpler mechanisms, and they remained in production (especially for export to the European markets).

This one is running sweetly after being repaired and fully serviced. Great amplitude and lots of power from an old stock blue steel mainspring. I originally got this movement to repair in 2017, when I had my watch repair shop in California, but never got around to it, until now in the spring of 2025. The balance staff was broken but I made the balance staff on my lathe, just for practice. Parts are readily available for these, but it is fun to make them from time to time.

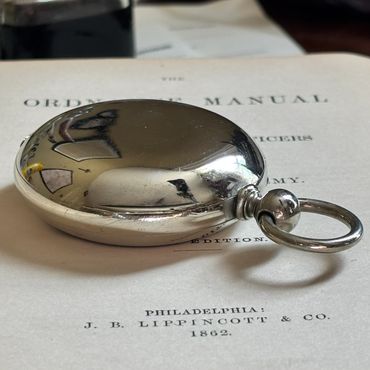

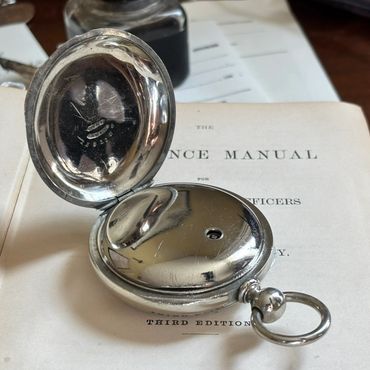

Dueber Silverine (nickel alloy) case is in good overall condition, all lids snap tightly shut -- this is how the watch cases were when they were new, and you will probably need a knife or other blade to help open the case. Eventually cases wear out and get loose, but this one has seen very little wear and is still nice and tight. Nice new clear crystal that is a little thinner than I'd prefer for an open face watch but it will do the job.

Dial is good with some hairlines present, but no chips or flakes.

Comes with a key.

$195

PA residents add 6% sales tax

Free pickup at the shop in Gettysburg PA, or insured shipping to US addresses for $15

Repairs and restoration of this watch

This movement had a broken balance and a missing roller jewel… which was no surprise because instead of shellac, somebody used epoxy glue to hold the jewel in place.

You can find replacement balance staffs for these common Waltham’s for about $10 but I wanted to practice on my lathe, so I made this one.

In the chuck on the lathe. I did not do a very good job on the top pivot and had to finish it on a special pivot polishing tool. But this is why I practice!

Fitting the staff to the balance wheel after shaping the pivots properly (and looking much better). If you look closely you can see the cut made in the staff that will form a rivet when staked onto the balance wheel.

Riveted to the balance wheel and now ready for poising. The process of knocking out the old balance and fitting the replacement will almost inevitably put the balance wheel out of true flat and round, and you can even see the bent arm in the picture. This is corrected with help of some poising calipers.

Copyright © 2025 Key Wind Watch - All Rights Reserved.